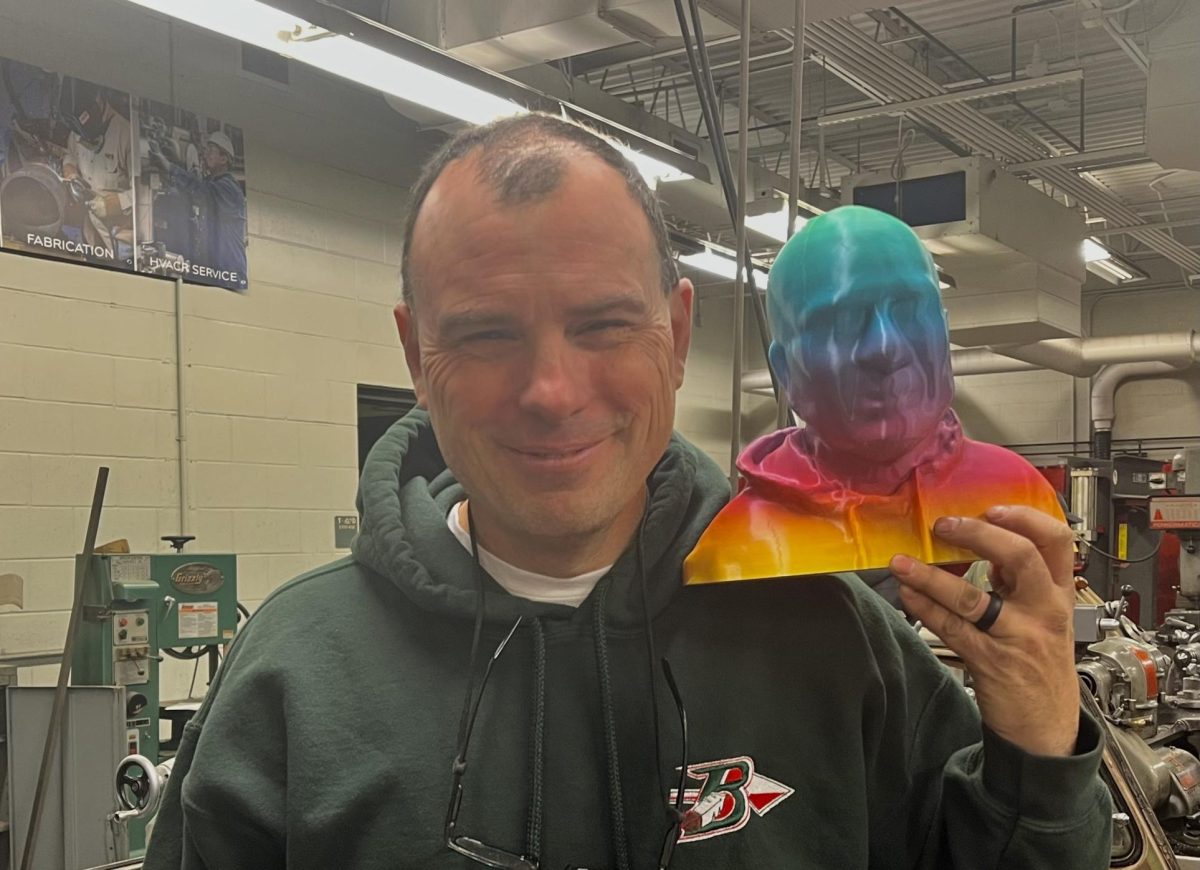

Last semester, tech and engineering teacher Bryan Evans taught a class called Engineering and Design, where they did a project with a 3D printer. For the project, the students came up with printing tech and engineering teacher Bret Steffen’s head.

“It was a big surprise and felt good – I don’t think they were trying to be too mean!” Steffen said.

Before this project, the 3D printer hadn’t been used since Evans started working at Berlin High School. He plans to start using it more in the future.

“It helps keep the students focused because they know if they complete their models on our software (Autocad, Onshape) they get to print them out. It helps create a sense of accomplishment,” Evans said.

The first step in wanting to make a 3D printed model was getting Steffen’s head made into a digital design on a computer. To do that they took multiple pictures at different angles and sides of Steffen’s head and uploaded them into software that allows the student to make the digital design that the 3D Printer could use to make the model. Students needed to use a system called Afinia 3D Studio Software to make the design. Once the 3D printer had the design it could start making the model.

Senior Tom Schumacher was one of the students taking Evans’s Engineering and Design class. He was also one of the students who worked on the 3D model project, fixing a problem with the bottom of the model.

“We took a picture of him against a blank background and used an AI software to generate a 3D model from that picture. Then I converted that model to an STL (stands for stereolithography, a popular 3D printing technology), imported it into Cura to create a G-code file, and tried printing it, but ran into issues because the model did not have a flat bottom. So I imported it into CAD software and trimmed the bottom so it would be flat and sit on the printer better, then repeated the process of printing it,” Schumacher said.

The printing process took 72 hours to complete and was made of Afinia 3D Premium Filament. 1000g, 1.75 mm. Now the model resides in the tech ed display case near the nurse’s office

“The kids in the engineering class obviously have too much time and skill on their hands,” Steffen said

Tech and engineering teacher Bret Steffen’s head gets 3D printed. “It involves creating a digital design on a computer, which is then sliced into thin layers, and the printer builds the object layer by layer by depositing material (like plastic or metal) according to the digital instructions, fusing each layer together to form the final 3D object; essentially, it’s like building something with tiny stacked slices instead of a solid block,” Evans said.